The Section for Long-Term Care Regulation will be releasing a series of Life Safety Code Information. You may also view the entire Life Safety Code document for reference.

Today’s subject is:

The facility must test receptacles (outlets) annually.

-

- What are the four test needed on non-hospital grade outlets?

- Are facilities required to document each electrical outlet annually?

- What documentation should the facility retain for each electrical receptacle?

- What happens if an outlet fails the inspection?

- What inspections does the facility need for hospital-grade outlets?

NFPA 99, 2012 edition:

6.3.3.2 Receptacle Testing in Patient Care Rooms.

6.3.3.2.1 The physical integrity of each receptacle shall be confirmed by visual inspection.

6.3.3.2.2 The continuity of the grounding circuit in each electrical receptacle shall be verified.

6.3.3.2.3 Correct polarity of the hot and neutral connections in each electrical receptacle shall be confirmed.

6.3.3.2.4 The retention force of the grounding blade of each electrical receptacle (except locking-type receptacles) shall be not less than 115 g (4 oz.).

The facility needs to document every outlet in the patient areas. The inspection report needs to show every outlet tested and includes areas such as resident rooms. The facility staff need to complete all four tests annually. These inspections may be a pass/fail for the four tests; however, the pass/fail must be for each specific test (e.g. grounding, polarity), and the pass/fail cannot just be for the outlet.

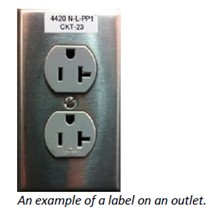

If the facility does not label every outlet, then there needs to be a system so everyone reading the documentation will know which outlet was tested. An example could be starting at the entrance, going around the room clockwise/counter clockwise, and naming the first outlet A, the second B and so on, until all outlets are recorded on the inspection sheet. The facility needs to document their system and use the same system throughout the facility. If one or more of the outlets in a room/area are hospital grade, the facility staff may document it on the form to show why annual testing did not occur (if applicable).

When an outlet fails any of the four tests, the facility needs to replace the outlet with a hospital grade outlet and staff need to document they replaced the outlet on the inspection sheet.

For any hospital grade outlet, the facility must create a system to complete a risk assessment and decide how often they want to complete the maintenance/testing, which can be longer than annually. The risk assessment system must be in place as soon as the facility has a hospital grade outlet. When due for an inspection and testing, these outlets must also be individually itemized on the documentation.

NFPA 99, 2012 edition:

10.3 Testing Requirements – Fixed and Portable.

10.3.1* Physical Integrity. The physical integrity of the power cord assembly composed of the power cord, attachment plug, and cord-strain relief shall be confirmed by visual inspection.

10.3.2* Resistance.

10.3.2.1 For appliances that are used in the patient care vicinity the resistance between the appliance chassis, or any exposed conductive surface of the appliance, and the ground pin of the attachment plug shall be less than 0.50 ohm under the following conditions:

(1) The cord shall be flexed at its connection to the attachment plug or connector.

(2) The cord shall be flexed at its connection to the strain relief on the chassis.

10.3.2.2 The requirement of 10.3.2.1 shall not apply to accessible metal parts that achieve separation from main parts by double insulation or metallic screening or that are unlikely to become energized (e.g., escutcheons or nameplates, small screws).

10.3.3* Leakage Current Tests.

10.3.3.1 General.

10.3.3.1.1 The requirements in 10.3.3.2 through 10.3.3.4 shall apply to all tests.

10.3.3.1.2 Tests shall be performed with the power switch ON and OFF.

10.3.3.2 Resistance Test. The resistance tests of 10.3.3.3 shall be conducted before undertaking any leakage current measurements.

10.3.3.3* Techniques of Measurement. The test shall not be made on the load side of an isolated power system or separable isolation transformer.

10.3.3.4* Leakage Current Limits. The leakage current limits in 10.3.4 and 10.3.5 shall be followed.

10.3.4 Leakage Current – Fixed Equipment.

10.3.4.1 Permanently wired appliances in the patient care vicinity shall be tested prior to installation while the equipment is temporarily insulated from ground.

10.3.4.2 The leakage current flowing through the ground conductor of the power supply connection to ground of permanently wired appliances installed in general or critical care areas shall not exceed 10.0 mA (ac or dc) with all grounds lifted.

10.5.2.1 Testing Intervals.

10.5.2.1.1 The facility shall establish policies and protocols for the type of test and intervals of testing for patient care–related electrical equipment.

10.5.2.1.2 All patient care–related electrical equipment used in patient care rooms shall be tested in accordance with 10.3.5.4 or 10.3.6 before being put into service for the first time and after any repair or modification that might have compromised electrical safety.

10.3.5.4 Touch Leakage Test Procedure. Measurements shall be made using the circuit, as illustrated in Figure 10.3.5.4, with the appliance ground broken in two modes of appliance operation as follows:

(1) Power plug connected normally with the appliance on

(2) Power plug connected normally with the appliance off (if equipped with an on/off switch)